OK, so what is malt?

Processed barley grain that had the grain starches converted to sugars when going through the malting process. Brewers have available to them a large number of malts. However, the basic categories of malts are;

Malts that require mashing and sparging to extract the simple sugars.

Malts that can be steeped to take advance of their vast flavors and aromas they can impart to beer.

Any of the specialty malts and crystal malts (caramel malts), steeped because their compounds (sugar and flavor) are available as-is. Run them through a grain mill to crush them, and then steeping them will impart their aroma and flavors to the beer.

Those malts and grains that require mashing and sparging are mostly made up of starches, so the brewer is required to convert the starches to sugar.

Extract brewers, use only steeping type malts to add flavor and aromas to their beer.

Why are barley malts usually used?

Because of their high enzyme content, barley malts are used to brew beer more than any other kind of cereal malt. Enzymes convert starch within the grain into simple sugars. Plus, barley contains required yeast nutrition – protein.

Although not as widely used for brewing, other grains are Rye, Wheat, Oats, Maize (corn) Rice, Amaranth, Spelt, Millet, and Quinoa. Many of the listed grains above are not malted.

There is more than one classification of barley varieties grown,

2-row – This type used as the main malt base among home brewers. As the name indicates this variety has two kernels on the stalk, with those kernels being larger and have a higher extract yield than the 6-row kernels.

6-row – This variety has six kernels on the stalk and is used by brewers to add certain qualities not available from 2-row barley.

Each variety has its advantages and disadvantages for beer brewing.

Characteristics of the Malt Forms.

Malt Extract – This malt was mashed to extract the simple sugars, and then concentrated to a syrup or powder by professional brewers.

Base Malts – This is the primary malt and compose the bulk of the grain bill used by brewers. These lighter-colored workhorse malts provide the majority of the proteins, fermentable sugars, and minerals required to create beer.

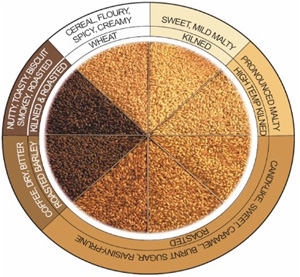

Specialty Malts – The malts is this form were further treated by kilning them at a higher temperature and for longer time periods. These kilning processes darken the malt color and create various aromas and flavors.

Specialty malts, due to additional roasting and toasting develops malt without enzymes required to convert starches to sugar when mashed. Brewers use small quantities of specialty grains along with base malts, extracts and adjuncts to provide additional characteristics to the beer. Some of these features are; head retention, flavor, color, body, and aromas.

UNMALTED BARLEY – An essential aspect for styles such as dry stout because it imparts a rich, grainy character to the beer. Many brewers use unmalted barley to help with head retention. However, it does have a problem; it will make beer hazy.

WHEAT: Advantages

Creates a full body and mouthfeel.

Head retention and foamy head.

Impart a slight tartness and haziness, great for brewing a hefeweizen or witbier.

CORN: Advantages

A smooth, somewhat neutral sweetness.

Lighten a beer’s body.

Stabilize flavor.

Decrease haziness.

OATS: Advantages – When used with barley.

Full-bodied creamy brew in the glass.

Often used in the grain bill of stouts.

RICE: Advantages

Lighten beer body.

Creates a dry profile.

Creates snappy flavors, with no discernible taste.

RYE: Advantages – When used with barley.

Sharpen flavors

Add complexity

Subtle spiciness and crispness.

Creates a dry profile

Disadvantage

No husks (hulls), meaning don’t use a high percentage of rye in your grain bill, or your mash will become very gummy and clump up and cause a stuck mash. Brewers call this, “Lake Mash Tun.”