Before the brewer can use the barley, it must have the non-convertible starch converted to soluble starch. This process is called malting. Malting also reduces complex protein, generates nutrients for yeast growth, during the germination process.

Contents

Malting process

The three steps are required to malt barley.

Steeping

The purpose of steeping step is to have the grain kernels absorb moisture. Steeping is accomplished by spraying with water or water immersion of the grain during controlled cycles of spraying and aeration until the moisture content of the gain reaches 42-48%.

Germination

After approximately 24 hours, the appearance of a white root will be the visible sign that germination has started

The maltster then transfers the grain to a malting bed where the germination is allowed to proceed for the next five or six days. The maltster can control the speed of germination by controlling the temperature, the aeration, plus maintaining the moisture content with spraying the malt bed. Controlling the length of time the acrospire (new plant) will grow will determine the amount of malt modification. We discuss malt modification in detail later in this article.

Greater development of the rootlets and acrospires during additional embryo growth may lead to root entangling. For prevention of matting, a rotating screw or rack keeps the grain bed turned.

Kilning

After five or six days of germination, the green malt has a flow of hot air forced through it, which kiln dries and partly cooks the malt.

Purpose: Stopping the biochemical and biological processes by removing the water and heating the grain by forcing hot air through it, which prevents enzyme activities started via germination.

Moisture content should be 3%-5% for storage stability. Kilned malt is stable for storage and has a texture suitable for the milling process that proceeds brewing.

Change the flavor, aroma and improve malt color by kilning at higher temperatures and length of time in kiln, examples of various malts:

Base Malts – Pale malt, Mild pale ale, Pilsen malt, Vienna, and Munich malt. For details of these malts see, Base Malts Article

Specialty Malts – Caramel/Crystal Malts, Special Roast Malt, Pale Chocolate Malt, and many more see, Specialty Malts Article

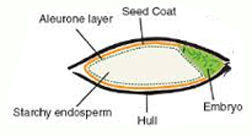

What’s in the barley kernel?

The barley kernel has four very necessary parts.

The husk (Hull) – The outermost layer a tough coat that surrounds the seed. Survival of the seed partway through the malting process is due to the husk. (although alive at the beginning of the malting process, it is killed when the kilning process begins).

The husk helps separate the particles in the mash and sets up a filter bed that is essential for easy sparging. It would be difficult to run off the sweet wort successfully from the grains if we did not have a filter bed formed with the help of the husk.

The aleurone – This is the next part of the barley kernel, also known as the seed coat. Enzymes secreted from this thin layer are vital to mashing processes.

The embryo (Germ) – Is the control center for germination.

The endosperm – The barley kernel’s non-living part in which starches and other food for the embryonic plant reside. A shoot (new plant) grows beneath the husk is known as the acrospire.

During germination and growth of this shoot, enzymes are produced that break down the non-soluble starches and proteins within the endosperm into soluble starches, simple sugars, and amino acids to nourish the growing plant. The proteins give the yeasts the nutrients required for a healthy fermentation.

The barley kernel provides everything the brewer requires to brew a great beer. Now you understand why the brewer requires access to all of these parts of the kernel. A properly adjusted mill gives the brewer the best crush that will provide the access to everything in the grain. There are different mills available to the home brewer. Grain Mills Article

Malt Modification

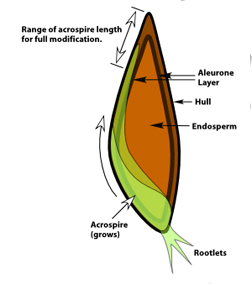

In the discussion above, we learned that during germination, a new embryonic plant (acrospire) grows beneath the husk from the bottom of the kernel along the opposite side of the crease. During germination, the maltster wants to maximize useful enzymes production. However, they need to stop the process before the plant consumes too much of the starches.

The most important process that is required to take place during germination is Protein Modification An insoluble protein-glucan matrix of starch granules embedded in the endosperm. This matrix must be broken down to release the action of the amylase enzymes, which are critical to malting and mashing processes. Breaking down of the protein-glucan matrix and to what degree refers to as modification. This modification changes the grain physically from being hard to soft or mealy.

The release of enzymes provides food for the growing plant. Therefore modification mirrors the progress of the acrospire as it grows up the kernel. As the acrospire grows longer the modification increases.

During the germination process, the barley is examined to see when germination is complete. Germination is complete when the new growth stems out from the end of the kernels and up the back of the grain (acrospire}.

Malt Modification classifications

- Fully modified – acrospire is roughly the same length as the kernel.

- Over modified – acrospire is longer than the kernel size.

- Under modified – Acrospire is shorter than the kernel size.

The length of the germination period will determine the amount of modification.